Parameters

| Single pump weight | 870kg |

| Single pump shape | 1450×700×580 (mm) |

| Maximum pressure | 150Mpa |

| Maximum flow | 120L/min |

| Optional speed ratio | 4.04:1, 4.62:1, 5.44:1 |

| Recommended oil | Shell pressure S2G 200 |

Features

1. The PW-3D3Q is one of the leading models in its category, boasting a range of features that differentiate it from conventional pumps.

2. The pump features a three-piston design designed to provide superior performance in high-pressure applications. Use with electric motors further enhances its functionality, making it a versatile and efficient solution for a variety of industrial needs.

3. One of the key features of the PW-3D3Q is its forced lubrication and cooling system, which ensures the long-term stability of its power end.

Product Details

Application Areas

★ Traditional Cleaning (Cleaning Company)/Surface Cleaning/Tank Cleaning/Heat Exchanger Tube Cleaning/Pipe Cleaning

★ Paint Removal From Ship/Ship Hull Cleaning/Ocean Platform/Ship Industry

★ Sewer Cleaning/Sewer Pipeline Cleaning/Sewer Dredging Vehicle

★ Minning, Dust Reduction By Spraying In Coal Mine, Hydraulic Support, Water Injection To Coal Seam

★ Rail Transit/Automobiles/Investment Casting Cleaning/Preparation For Highway Overlay

★ Construction/Steel Structure/Descaling/Concrete Surface Preparation/Asbestos Removal

★ Power Plant

★ Petrochemical

★ Aluminium Oxide

★ Petroleum/Oil Field Cleaning Applications

★ Metallurgy

★ Spunlace Non-Woven Fabric

★ Aluminium Plate Cleaning

★ Landmark Removal

★ Deburring

★ Food Industry

★ Scientific Research

★ Military

★ Aerospace, Aviation

★ Water Jet Cutting, Hydraulic Demolition

Recommended working conditions:

Heat exchangers, evaporation tanks and other scenarios, surface paint and rust removal, landmark cleaning, runway degumming, pipeline cleaning, etc.

Cleaning time is saved due to excellent stability, ease of operation, etc.

It improves efficiency, saves personnel costs, liberates labor, and is simple to operate,and ordinary workers can operate without training.

(Note: The above working conditions need to be completed with various actuators, and the purchase of the unit does not include all kinds of actuators, and all kinds of actuators need to be purchased separately )

Characteristic

1. - High Pressure: Our plunger pumps are capable of delivering ultra-high pressure, making them suitable for demanding industrial applications.

2. - Stability: The forced lubrication cooling system ensures long-term stable operation of the power end and reduces maintenance and downtime.

3. - Compatibility: Pumps can be easily integrated with motors, providing versatility and convenience for different industrial settings.

FAQ

Q1: What are the advantages of using ultra-high pressure plunger pump?

A: Ultra-high pressure piston pumps are known for their ability to generate high pressures, making them ideal for applications that require powerful forces such as cutting, cleaning and descaling.

Q2: How do forced lubrication and cooling systems benefit pump operation?

A: The forced lubrication and cooling system in our PW-3D3Q model ensures smooth and efficient operation of the power end for a long time, reducing the risk of overheating and wear.

Q3: Can the pump be used with a motor?

A: Yes, our PW-3D3Q model is designed to be motor compatible, providing flexibility and ease of use in a variety of industrial settings.

Our advantage

1. Our company is located in Tianjin, one of the largest cities in China, at the forefront of advanced technology industries. Tianjin has a population of 15 million and is a center for aviation, electronics, machinery, shipbuilding and chemistry. This environment allows us to develop and produce high-quality innovative products, such as the PW-3D3Q ultra-high pressure piston pump.

2. We are proud of our commitment to excellence and customer satisfaction. The PW-3D3Q is a testament to our commitment to providing top-notch solutions for high-pressure pumping needs. With its advanced features and rugged construction, the pump is expected to make a major impact across various industries.

3. The PW-3D3Q ultra-high pressure piston pump is a game changer in the high pressure pump world. Its superior design, reliable performance and compatibility with motorized three-piston pumps make it the best choice for businesses looking for reliable, efficient pumping solutions.

Company Information:

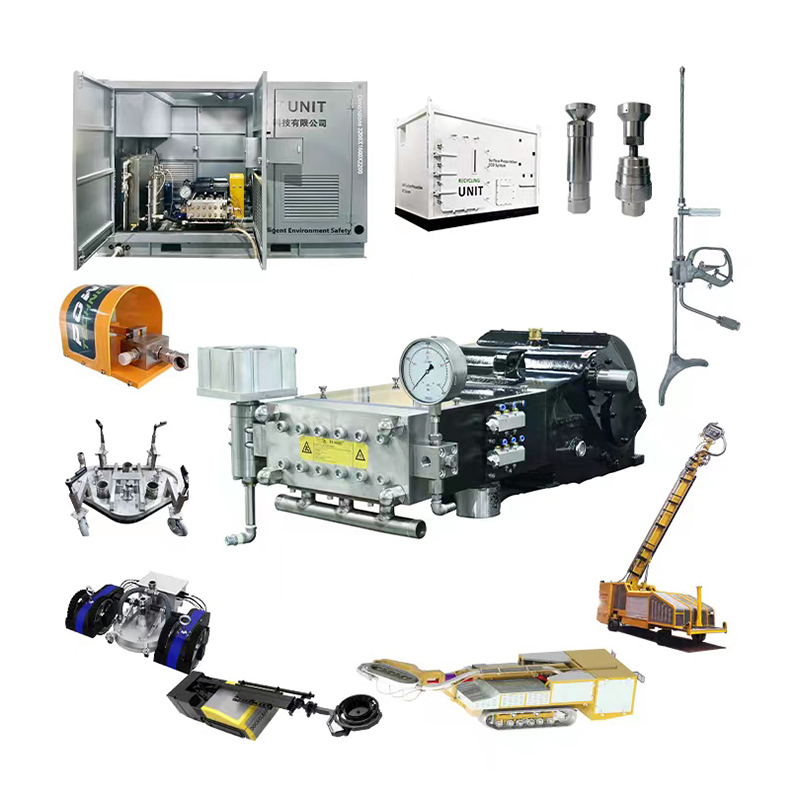

Power (Tianjin) technology Co., Ltd. is a high-tech enterprise integrating R&D and manufacturing of HP and UHP water jet intelligent equipment, cleaning engineering solutions, and cleaning. The business scope involves many fields such as shipbuilding, transportation, metallurgy, municipal administration, construction, petroleum and petrochemical, coal, electric power, chemical industry, aviation, aerospace, etc. Production of various types of full automatic and semi-automatic professional equipments.

In addition to company headquarters, there are overseas offices in Shanghai, Zhoushan, Dalian, and Qingdao. The company is a nationally recognized high-tech enterprise. Patent achievement enterprise.and also is member units of multiple academic groups.

Quality Test Equipment:

Workshop Display:

Exhibition: