Parameters

| Single pump weight |

780kg |

| Single pump shape | 1500X800X580(mm) |

| Maximum pressure | 280Mpa |

| Maximum flow | 635L/min |

| Rated shaft power | 200KW |

| Optional speed ratio | 4.04.1 4.62:1 5.44:1 |

| Recommended oil | Shell pressure S2G 220 |

Product Details

Description

Our high-pressure pumps have forced lubrication and cooling systems to ensure long-term stable operation of the power end. This innovative design not only enhances the pump's durability but ensures consistent and efficient performance even in the most demanding industrial environments.

Focused on precision engineering and advanced technology, our triple piston pumps provide the high pressure and high flow capabilities required for a variety of applications, including water spraying, industrial cleaning and surface treatment. Whether you need to remove tough coatings, clean large industrial equipment or tackle challenging cleaning tasks, our high-pressure pumps are up to the challenge.

As a company headquartered in Tianjin, one of China's largest and most advanced cities, we are proud to bring cutting-edge technology to global markets. Tianjin is famous for its aviation, electronics, machinery, shipbuilding, chemical and other industries, making it an ideal place to develop and produce high-quality industrial equipment.

We understand the importance of reliability and performance in high-pressure pump applications, which is why our waterjet plunger pumps are designed to exceed expectations. Backed by our commitment to quality and innovation, our high-pressure pumps are ideal for businesses and industries that require optimal performance and durability.

Features

1. In the field of industrial technology, Tianjin stands out for its innovation and progress, especially in the field of high-voltage equipment. One example is the high-pressure triplex piston pump, a cutting-edge product that attracts attention for its superior functionality and performance.

2. High-pressure pumps are designed with reliability and longevity in mind. Forced lubrication and cooling systems are adopted to ensure long-term stable operation of the power end. This capability is critical for industries that rely on continuous, high-intensity operations, such as manufacturing, oil and gas, and construction.

3. Tianjin’s advanced technology industries play a key role in the development and production of high-pressure pumps, contributing to the city’s reputation as a center for technological innovation. With a strong focus on research and development, the Tianjin company has been able to manufacture high-quality, precision-engineered pumps that meet the demanding requirements of a variety of industrial applications.

4. In addition, Tianjin’s good foreign business environment also promotes cooperation and partnerships in the field of high-voltage equipment. International companies find a welcoming and supportive ecosystem in Tianjin, allowing them to tap into the city’s resources and expertise to enhance their product offerings.

5. As Tianjin continues to evolve as a center for advanced technology, the high-pressure triplex piston pump demonstrates the city’s commitment to excellence and innovation. With its powerful features and support from Tianjin’s vibrant industrial landscape, the product embodies the synergy between cutting-edge technology and a booming business environment.

Advantage

1. Forced lubrication and cooling system: One of the main advantages of high-pressure pumps is the use of forced lubrication and cooling systems. This ensures long-term stable operation of the power end and reduces the risk of overheating and wear.

2. High Pressure and Flow: These pumps are capable of delivering extremely high pressure and flow, making them suitable for demanding applications that require intense cleaning or cutting.

3. Durability: High-pressure triplex piston pumps are built to withstand the rigors of industrial use, and many models feature rugged construction and high-quality materials for extended service life.

Shortcoming

1. Maintenance requirements: While forced lubrication and cooling systems contribute to pump stability, they also require regular maintenance to ensure optimal performance. This increases the total cost of ownership.

2. Initial investment: High-pressure pumps often require a large initial investment, which can be a deterrent for some businesses, especially small businesses.

3. Noise and vibration: The operation of high-pressure pumps produces significant noise and vibration, and appropriate measures need to be taken to mitigate these effects in the workplace.

Application Areas

★ Traditional Cleaning (Cleaning Company)/Surface Cleaning/Tank Cleaning/Heat Exchanger Tube Cleaning/Pipe Cleaning

★ Paint Removal From Ship/Ship Hull Cleaning/Ocean Platform/Ship Industry

★ Sewer Cleaning/Sewer Pipeline Cleaning/Sewer Dredging Vehicle

★ Minning, Dust Reduction By Spraying In Coal Mine, Hydraulic Support, Water Injection To Coal Seam

★ Rail Transit/Automobiles/Investment Casting Cleaning/Preparation For Highway Overlay

★ Construction/Steel Structure/Descaling/Concrete Surface Preparation/Asbestos Removal

★ Power Plant

★ Petrochemical

★ Aluminium Oxide

★ Petroleum/Oil Field Cleaning Applications

★ Metallurgy

★ Spunlace Non-Woven Fabric

★ Aluminium Plate Cleaning

★ Landmark Removal

★ Deburring

★ Food Industry

★ Scientific Research

★ Military

★ Aerospace, Aviation

★ Water Jet Cutting, Hydraulic Demolition

Recommended working conditions:

Heat exchangers, evaporation tanks and other scenarios, surface paint and rust removal, landmark cleaning, runway degumming, pipeline cleaning, etc.

Cleaning time is saved due to excellent stability, ease of operation, etc.

It improves efficiency, saves personnel costs, liberates labor, and is simple to operate,and ordinary workers can operate without training.

(Note: The above working conditions need to be completed with various actuators, and the purchase of the unit does not include all kinds of actuators, and all kinds of actuators need to be purchased separately )

FAQ

Q1:What is a high-pressure triplex piston pump?

A high-pressure triplex piston pump is a positive displacement pump that uses three plungers to move fluid at high pressure. These pumps are commonly used in aerospace, electronics, mechanical, shipbuilding and chemical applications where high pressure and reliability are required.

Q2:How does it work?

These pumps operate by the reciprocating motion of a plunger to produce smooth and consistent fluid flow at high pressures. They are known for their efficiency and ability to handle a variety of fluids, making them a versatile choice for many applications.

Q3:What are the main features?

The high-pressure pump adopts forced lubrication and cooling systems to ensure long-term stable operation of the power end. This feature is critical to maintaining pump performance and service life, especially in demanding industrial environments.

Q4:Why choose high pressure triple cylinder plunger pump?

These pumps are favored for their ability to handle high pressures, durability, and versatility in handling a variety of fluids. In a city like Tianjin, known for its advanced technology industries, these pumps are critical to powering critical processes in manufacturing and production.

Company Information:

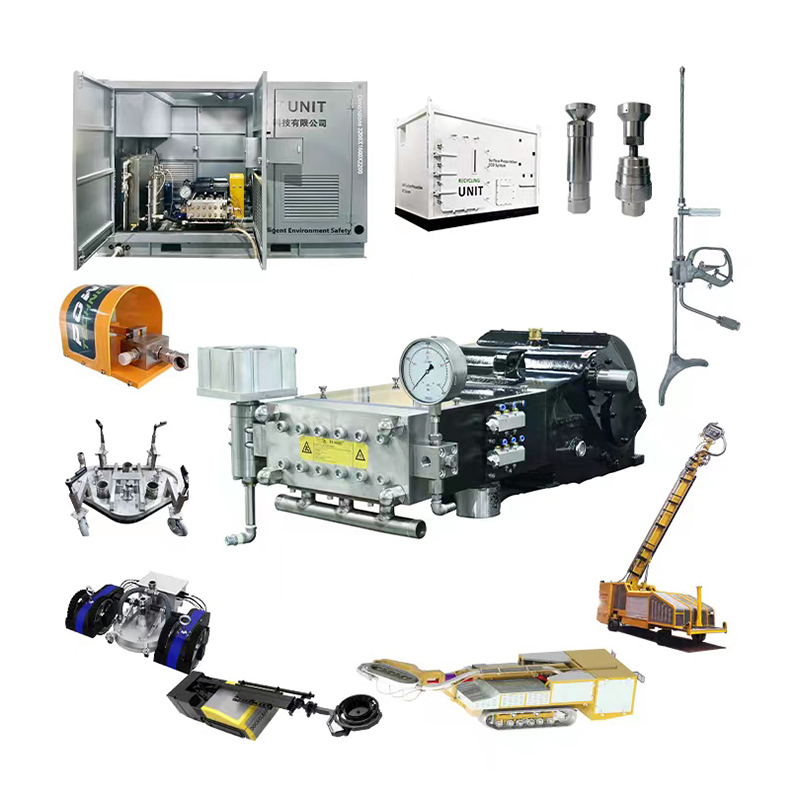

Power (Tianjin) technology Co., Ltd. is a high-tech enterprise integrating R&D and manufacturing of HP and UHP water jet intelligent equipment, cleaning engineering solutions, and cleaning. The business scope involves many fields such as shipbuilding, transportation, metallurgy, municipal administration, construction, petroleum and petrochemical, coal, electric power, chemical industry, aviation, aerospace, etc. Production of various types of full automatic and semi-automatic professional equipments.

In addition to company headquarters, there are overseas offices in Shanghai, Zhoushan, Dalian, and Qingdao. The company is a nationally recognized high-tech enterprise. Patent achievement enterprise.and also is member units of multiple academic groups.

Quality Test Equipment:

Workshop Display:

Exhibition: