Parameters

| Single pump weight | 260kg |

| Single pump shape | 980×550×460 (mm) |

| Maximum pressure | 280Mpa |

| Maximum flow | 190L/min |

| Rated shaft power | 100KW |

| Optional speed ratio | 2.75:1 3.68:1 |

| Recommended oil | Shell pressure S2G 220 |

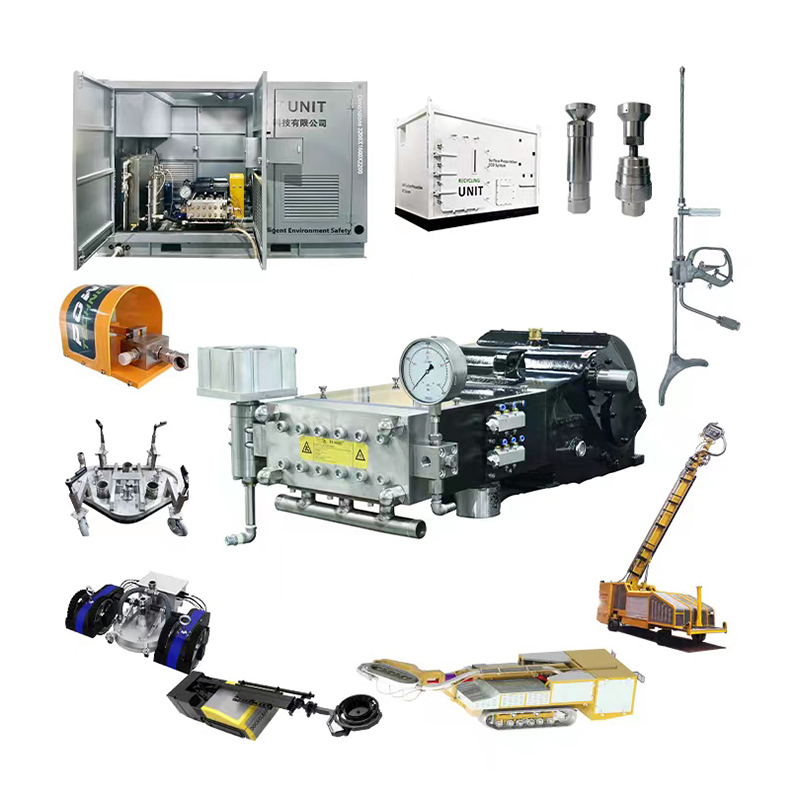

Product Details

Features

1. High pressure pump adopts forced lubrication and cooling system to ensure long-term stable operation of power end;

2. The crankshaft box of the power end is cast with ductile iron, and the cross head slide is made of cold-set alloy sleeve technology, which is wear-resistant, low noise and compatible high precision;

3. Fine grinding of gear shaft and gear ring surface, low running noise; Use with NSK bearing to ensure stable operation;

4. The crankshaft is made of American standard 4340 high quality alloy steel, 100% flaw detection treatment, forging ratio 4:1, after survival, the whole nitriding treatment, compared traditional 42CrMo crankshaft, strength increased by 20%;

5. The pump head adopts high-pressure/water inlet split structure, which reduces the weight of the pump head and is easier to install and disassemble on site.

6. The plunger is tungsten carbide material with hardness higher than HRA92, surface accuracy higher than 0.05Ra, straightness and cylindricity less than 0.01mm, both ensure hardness and wear resistance also ensure corrosion resistance and improve service life;

7. The plunger self-positioning technology is used to ensure that the plunger is stressed evenly and the service life of the seal is greatly extended;

8. The stuffing box is equipped with imported V-type packing to ensure the high pressure pulse of high pressure water, long life;

Advantage

High Pressure and Flow

Effect

In this bustling city, there is always a need for high-quality construction equipment, and one of these essential tools is the triple plunger pump.

Triple piston pumps are critical components in construction and are known for their ability to provide high pressure and flow. These pumps offer several advantages that make them indispensable in the construction industry. A major feature of this pump is the use of forced lubrication and cooling systems to ensure long-term stable operation of the power end. This is critical for construction projects that require continued reliable performance of equipment.

Moreover, the power-end crankcase is made of ductile iron, and the crosshead slider uses cold-set alloy sleeve technology. This design ensures that the pump is wear-resistant, low-noise and maintains high precision. These features are particularly useful in construction environments where durability and precision are critical.

In the construction industry where efficiency and reliability are critical, the high pressure and flow capabilities of triple piston pumps make them a valuable asset. Whether it's concrete pumping, high-rise construction or tunneling, these pumps play a vital role in ensuring operations run smoothly and efficiently.

Application Areas

★ Traditional Cleaning (Cleaning Company)/Surface Cleaning/Tank Cleaning/Heat Exchanger Tube Cleaning/Pipe Cleaning

★ Paint Removal From Ship/Ship Hull Cleaning/Ocean Platform/Ship Industry

★ Sewer Cleaning/Sewer Pipeline Cleaning/Sewer Dredging Vehicle

★ Minning, Dust Reduction By Spraying In Coal Mine, Hydraulic Support, Water Injection To Coal Seam

★ Rail Transit/Automobiles/Investment Casting Cleaning/Preparation For Highway Overlay

★ Construction/Steel Structure/Descaling/Concrete Surface Preparation/Asbestos Removal

★ Power Plant

★ Petrochemical

★ Aluminium Oxide

★ Petroleum/Oil Field Cleaning Applications

★ Metallurgy

★ Spunlace Non-Woven Fabric

★ Aluminium Plate Cleaning

★ Landmark Removal

★ Deburring

★ Food Industry

★ Scientific Research

★ Military

★ Aerospace, Aviation

★ Water Jet Cutting, Hydraulic Demolition

Recommended working conditions:

Heat exchangers, evaporation tanks and other scenarios, surface paint and rust removal, landmark cleaning, runway degumming, pipeline cleaning, etc.

Cleaning time is saved due to excellent stability, ease of operation, etc.

It improves efficiency, saves personnel costs, liberates labor, and is simple to operate,and ordinary workers can operate without training.

(Note: The above working conditions need to be completed with various actuators, and the purchase of the unit does not include all kinds of actuators, and all kinds of actuators need to be purchased separately )

FAQ

Q1. What are the main features of your high-pressure three-piston pump?

Our pumps are designed to deliver high pressure and flow, making them suitable for a variety of construction applications. The forced lubrication and cooling system ensures the long-term stability of the power end, while the use of durable materials such as ductile iron and cold-set alloy sleeve technology enhances wear resistance and precision.

Q2. How can your pump benefit a construction project?

Our pumps are capable of meeting high pressure and flow requirements, making them ideal for tasks such as concrete pumping, hydrotesting and high-pressure cleaning. The reliability and efficiency of our pumps help increase productivity and reduce downtime on construction sites.

Q3. How does your high-pressure pump differ from other options on the market?

Our pumps are designed with durability, performance and precision in mind. The use of advanced materials and technology ensures our pumps can withstand the harsh construction environment while delivering consistent and reliable performance.

Q4. How do I choose the right high-pressure pump for my specific needs?

Our team of experts can work with you to assess your requirements and recommend the best pump for your application. Whether you need a pump for concrete pumping, hydrotesting or high-pressure cleaning, we can provide a tailor-made solution to meet your needs.

Company Information:

Power (Tianjin) technology Co., Ltd. is a high-tech enterprise integrating R&D and manufacturing of HP and UHP water jet intelligent equipment, cleaning engineering solutions, and cleaning. The business scope involves many fields such as shipbuilding, transportation, metallurgy, municipal administration, construction, petroleum and petrochemical, coal, electric power, chemical industry, aviation, aerospace, etc. Production of various types of full automatic and semi-automatic professional equipments.

In addition to company headquarters, there are overseas offices in Shanghai, Zhoushan, Dalian, and Qingdao. The company is a nationally recognized high-tech enterprise. Patent achievement enterprise.and also is member units of multiple academic groups.

Quality Test Equipment:

Workshop Display:

Exhibition: