Mekhahlelo

| Boima ba pompo e le 'ngoe | 260kg |

| Sebopeho sa pompo e le 'ngoe | 980×550×460 (mm) |

| Khatello e kholo | 280Mpa |

| Phallo e phahameng | 190L/min |

| Matla a shaft a lekantsoeng | 100KW |

| Boikhethelo karo-karolelano ea lebelo | 2.75:1 3.68:1 |

| Oli e khothalletsoang | Khatello ea likhetla S2G 220 |

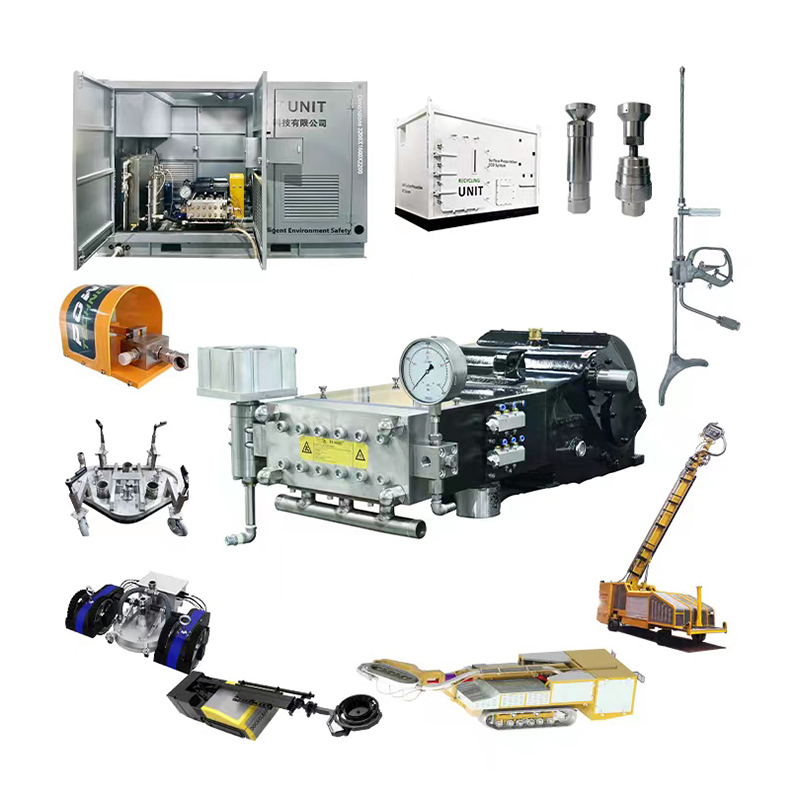

Lintlha tsa Sehlahisoa

Likaroloana

1. Pompo e phahameng ea khatello e amohela tsamaiso e qobelloang ea lubrication le pholileng ho etsa bonnete ba hore ts'ebetso e tsitsitseng ea nako e telele ea ho fela ha matla;

2. Lebokose la crankshaft la qetello ea matla le lahleloa ka tšepe ea ductile, 'me sefapano sa hlooho se slide se entsoe ka thekenoloji ea matsoho a batang a alloy, e sa sebetseng, lerata le tlaase le ho nepahala ho phahameng ho lumellanang;

3. Ho sila hantle ha shaft ea gear le bokaholimo ba selikalikoe, lerata le tlase le tsamaeang; Sebelisa e nang le NSK ho netefatsa ts'ebetso e tsitsitseng;

4. Crankshaft e entsoe ka tšepe ea boleng bo phahameng ba 4340 ea Amerika ea boleng bo phahameng, phekolo ea 100% ea ho lemoha liphoso, ho theha karolelano ea 4: 1, ka mor'a ho pholoha, phekolo eohle ea nitriding, ha e bapisoa le setso sa 42CrMo crankshaft, matla a eketseha ka 20%;

5. Hlooho ea pompo e amohela mohaho o arohaneng oa khatello e phahameng / metsi, e leng ho fokotsa boima ba hlooho ea pompo 'me ho bonolo ho kenya le ho qhaqha setšeng.

6. Plunger ke thepa ea tungsten carbide e nang le boima bo phahameng ho feta HRA92, ho nepahala ha holim'a metsi ho feta 0.05Ra, ho otloloha le cylindricity ka tlase ho 0.01mm, ka bobeli ho netefatsa ho thatafala le ho apara ho hanyetsa ho boetse ho tiisa ho hanyetsa kutu le ho ntlafatsa bophelo ba tšebeletso;

7. Theknoloji ea ho iketsetsa sebaka sa plunger e sebelisetsoa ho etsa bonnete ba hore plunger e hatelloa ka mokhoa o ts'oanang le bophelo ba tšebeletso ea tiiso bo atolosoa haholo;

8. Lebokose la ho roala le na le thepa ea mofuta oa V e tsoang linaheng tse ling ho netefatsa hore ho na le khatello e phahameng ea khatello ea metsi a phahameng, bophelo bo bolelele;

Libaka tsa Kopo

★ Ho Hloekisa ka Setso (Khampani ea ho Hloekisa)/Ho Hloekisa Bokahohle/Ho Hloekisa Tanka/Ho hloekisoa ha Mocheso ho Hloekisa Tube/Ho Hloekisa Lipeipi

★ Ho Tlosa Pente Ho Tloha Sekepe / Sekepe sa Hull Cleaning / Ocean Platform / Indasteri ea Likepe

★ Ho hloekisoa ha likhoerekhoere / Ho hloekisa Lipeipi tsa likhoerekhoere / Koloi ea ho Hlakola Likhoerekhoere

★ Morafo, Phokotso ea Lerōle Ka Ho Fafatsa Morafong oa Mashala, Tšehetso ea Hydraulic, Ente ea Metsi ho Seam ea Mashala

★ Rail Transit / Automobiles / Investment Casting Cleaning / Tokisetso Bakeng sa Highway Overlay

★ Sebopeho sa Moaho/Sebopeho sa Tšepe/Ho theola/Ho Lokisoa ha Bokaho ba Konkreite/Tloso ea Asbestos

★ Setsi sa Matla

★ Petrochemical

★ Aluminium oxide

★ Lisebelisoa tsa ho Hloekisa Tšimo ea Oli / Oli

★ Metallurgy

★ Lesela le sa Lohiloeng la Spunlace

★ Aluminium Plate Cleaning

★ Tloso ea Sebaka

★ Deburring

★ Indasteri ea Lijo

★ Patlisiso ea Saense

★ Sesole

★ Sefofane, Sefofane

★ Ho Seha Jet ea Metsi, ho Felisoa ha Hydraulic

Maemo a sebetsang a khothalelitsoeng:

Lisebelisoa tsa mocheso, litanka tsa mouoane le maemo a mang, pente e holim'a metsi le ho tlosa mafome, ho hloekisa libaka, ho hloekisa litsela tsa lifofane, ho hloekisa liphaephe, joalo-joalo.

Nako ea ho hloekisa e bolokiloe ka lebaka la botsitso bo babatsehang, boiketlo ba ts'ebetso, joalo-joalo.

E ntlafatsa ts'ebetso, e boloka litšenyehelo tsa basebetsi, e lokolla basebetsi, 'me e bonolo ho sebetsa, mme basebetsi ba tloaelehileng ba ka sebetsa ntle le koetliso.

(Tlhokomeliso: Maemo a ts'ebetso a kaholimo a tlameha ho phethoa ka li-activator tse fapaneng, 'me theko ea yuniti ha e kenyelle mefuta eohle ea li-activator,' me mefuta eohle ea li-activator e hloka ho rekoa ka thoko)

LBH

Q1. Ke khatello efe le sekhahla sa phallo ea metsi a UHP blaster eo hangata e sebelisoang ke indasteri ea sebaka sa likepe?

A1. Hangata 2800bar le 34-45L/M tse sebelisoang haholo ho hloekisa sebaka sa likepe.

Q2. Na tharollo ea hau ea ho hloekisa sekepe e thata ho sebetsa?

A2. Che, ho bonolo haholo ebile ho bonolo ho sebetsa, 'me re tšehetsa botekgeniki ba inthaneteng, video, ts'ebeletso ea matsoho.

Q3. U thusa joang ho rarolla bothata haeba re ne re kopana ha re sebetsa sebakeng sa mosebetsi?

A3. Ntlha ea pele, arabela ka potlako ho sebetsana le bothata boo u kopaneng le bona. 'Me haeba ho khonahala re ka ba sebaka sa hau sa ho sebetsa ho thusa.

Q4. Nako ea hau ea ho tlisa thepa le nako ea tefo ke efe?

A4. E tla ba matsatsi a 30 haeba e na le setoko, 'me e tla ba libeke tse 4-8 haeba u sena stock. Tefo e ka ba T/T. 30% -50% depositi esale pele, karolo e setseng pele ho pepa.

Q5. O ka reka eng ho rona?

A5. Sete ea pompo ea khatello e phahameng haholo, Sete ea pompo ea khatello e phahameng, Sete ea pompo ea khatello e mahareng, Roboto e kholo ea taolo e hole, Roboto ea ho hloa lebota ea taolo e hole.

Q6. Hobaneng o sa lokela ho reka ho rona ho tsoa ho barekisi ba bang?

A6. Khamphani ea rona e na le litokelo tse 50 tsa thepa ea mahlale. Lihlahisoa tsa rona li netefalitsoe ka nako e telele ke 'maraka,' me kakaretso ea thekiso e fetile li-yuan tse limilione tse 150. Khamphani e na le matla a ikemetseng a R&D le taolo e emeng. Maemong 'ohle re tla leka ho fana ka litlhoko tsa hau. Maemong a mangata re khona ho etsa joalo.

Tlhaloso

Likarolo tsa Bohlokoa:

1. Pompe ea khatello e phahameng e kenyelletsa tsamaiso e qobelloang ea lubrication le pholileng, ho netefatsa ts'ebetso e tsitsitseng ea nako e telele ea ho fela ha matla. Karolo ena e ikhethang e tiisa ts'ebetso e tsoelang pele ntle le litšitiso kapa ho senyeha.

2. Lebokose la crankshaft la qetello ea matla le entsoe ka tšepe ea ductile, e fanang ka matla a ikhethang le ho tiea. The cross head slide e entsoe ka thekenoloji ea sleeve ea alloy e sete e batang, e netefatsang ho se mamelle le ho fokotsa maemo a lerata. Ho feta moo, theknoloji ena e nolofalletsa ho lumellana le ts'ebetso e phahameng ea ho nepahala, ho etsa hore pompo ea rona e be e loketseng bakeng sa mefuta e mengata ea likopo.

3. Re lebisitse tlhokomelo e hlokolosi ho lintlha tsohle, ho kenyelletsa le ho sila hantle ha mochini oa gear le bokaholimo ba selikalikoe. Sena se etsa hore ho be le lerata le tlaase haholo, le etsang hore ho be le tikoloho e khutsitseng le e phutholohileng haholoanyane ea ho sebetsa. Ho feta moo, pompo ea rona ea khatello e phahameng e kenyelletsa li-bearings tsa NSK, tse tsebahalang ka ho ts'epahala le ho phela nako e telele, ho netefatsa ts'ebetso e bonolo le e tsitsitseng.

Ho feto-fetoha ha pompo ea rona ea khatello e phahameng hoa hlolla. E etselitsoe ka ho khetheha hore e sebetse ka katleho le lisebelisoa tse phahameng tsa khatello ea maikutlo le tse phahameng. Ka moralo oa eona oa li-plunger tse tharo, pompo ena e fana ka sekhahla sa phallo e ikhethang, e etsa hore e be se loketseng liindasteri tse fapaneng tse kang oli le khase, merafo, kaho le tse ling.

Pompo ea rona ea khatello e phahameng ha e finyelle litekanyetso tsa indasteri feela empa ea li feta ho latela ts'ebetso, ts'epahalo, le katleho. Motsoako oa tsamaiso ea eona e qobelloang ea ho tlotsa le ho pholisa, lebokose la ductile iron crankshaft, thekenoloji ea sleeve ea alloy-set, ho sila ka lisebelisoa tse ntle, le li-bearings tsa NSK li e khetholla ho tlhōlisano.

Lintlha tsa Khampani:

Power (Tianjin) technology Co., Ltd. ke khoebo ea theknoloji e phahameng e kopanyang R&D le ho etsa thepa e bohlale ea jete ea metsi ea HP le UHP, litharollo tsa boenjiniere tsa ho hloekisa, le ho hloekisa. Sebaka sa khoebo se kenyelletsa likarolo tse ngata tse kang kaho ea likepe, lipalangoang, tšepe, tsamaiso ea masepala, kaho, petroleum le petrochemical, mashala, matla a motlakase, indasteri ea lik'hemik'hale, lifofane, sefofane, joalo-joalo. .

Ntle le ntlo-kholo ea k'hamphani, ho na le liofisi tsa mose ho maoatle Shanghai, Zhoushan, Dalian le Qingdao. Khamphani ke khoebo e tsebahalang naheng ka bophara ea theknoloji e phahameng. Patent achievement enterprise.hape hape ke litho tsa lihlopha tse ngata tsa thuto.

Thepa ea Tlhahlobo ea Boleng:

Pontšo ea Seboka:

Pontšo:

-

Environmental Protection compact structure hori...

-

Horizontal plunger lipompo khatello e phahameng le phallo...

-

Pompo e phahameng ea khatello ea plunger e nang le pri ea tlholisano ...

-

Mokelikeli o sebetsanang le lipompo tsa plunger 2800 bar horizo ...

-

E entsoe ka China thekiso e chesang e phahameng khatello e holimo ...

-

Lipompo tsa mochini o qhomisang metsi lipompo tsa mochini o phatlollang...